Quality Valves from Manual to Solenoid Drive

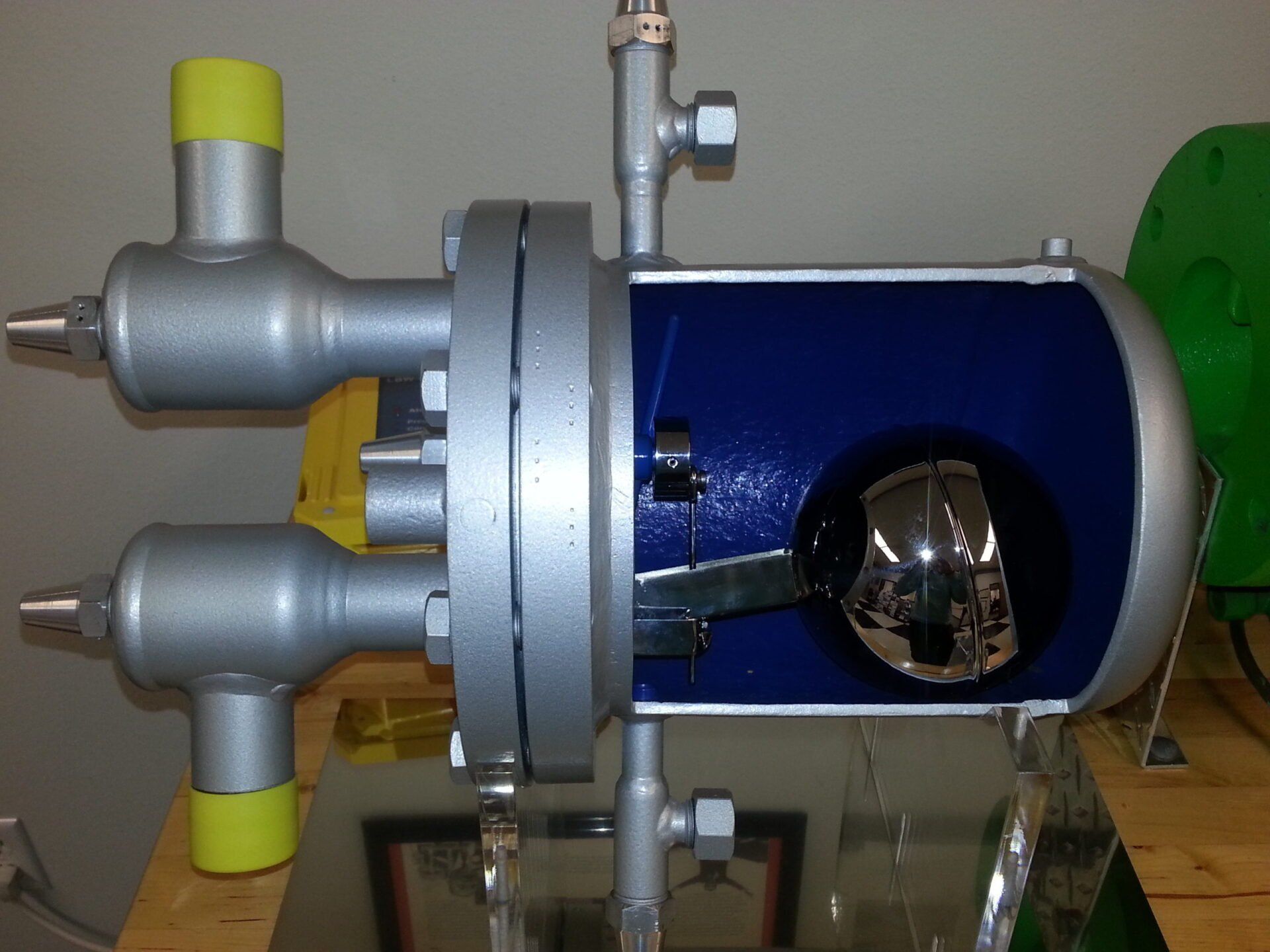

Refrigerant flow control valves are used to ensure that the refrigeration system is performing in accordance with the conditions as designed, particularly during partial load operation. All valves have some undesirable side effects, such as line pressure drop, except if is required by design, such as the throttling valve. Therefore, when making valve selection, it is important to select a valve that is producing less pressure drop.

All the valves must be checked to see if it is designed and constructed for refrigeration duty. Every valve used for the refrigeration system must serve the purpose it was designed for, regardless of whether it is a manual valve or automatic control valve. Manual stop valves are for the purpose of providing convenience of services and maintenance.

Manual valves also include the check valves and hand expansion. Manual expansion valves or needle valves are used as a throttling orifice in application wherever is required. All the valves used for system performance control or for system safety should be fully automatic.

The common use of automatic valves and their functions are described as follows:

City skyline

Solenoid valves

Solenoid Valves for High Safety and Reliability

First choice for control valves

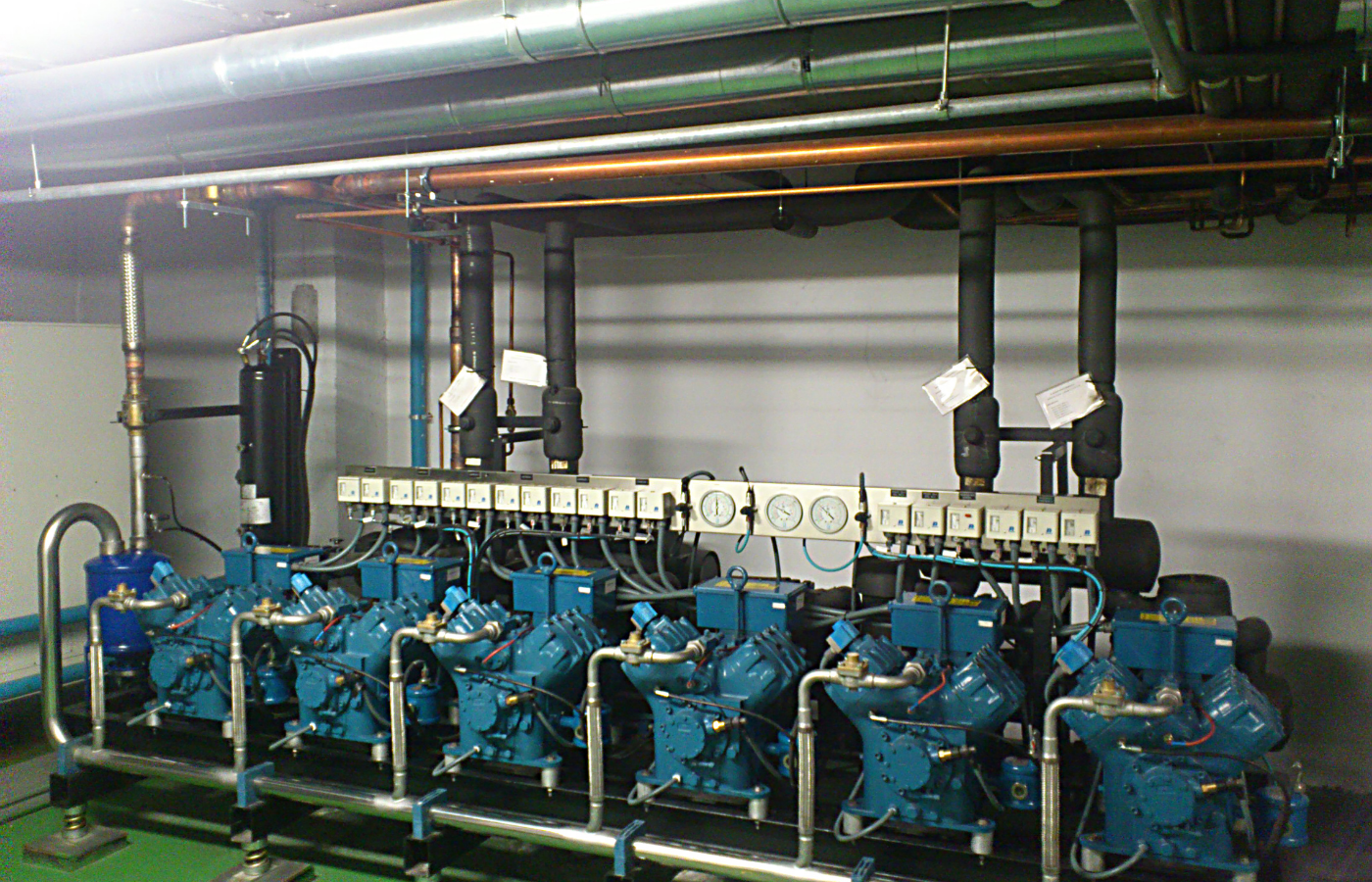

The direct-acting or pilot- operated solenoid valves can be used everywhere and are equipped with an excellent safety concept. They are popular control valves in the production lines of global leaders in chemical, petrochemical, refrigeration and pharmaceutical sectors, as well as in the oil and gas industry and are a favourite choice for controlling single-acting or double-acting actuators.

The solenoid valves are also extremely reliable and safe in fail-safe functions for safely switching off actuators with positioners.

City skyline

Perfect for the:

✔︎ Industrial Refrigeration Industry

✔︎ Chemical industry

✔︎ Petrochemical industry

✔︎ Oil and gas industry

✔︎ Pharmaceutical industry

Designed for the toughest demands

Including extreme environments

Certificates, expert opinions and testimonials demonstrate that these solenoid valves are suitable for the toughest demands when it comes to operational reliability, availability and flexibility in use. Even outdoors and in difficult environmental conditions. The world's most important types of ignition protection are offered: Ex me, Ex ia and Ex-d.

Reliable and safe

For reliable switching when needed

The high quality and resulting reliability of these solenoid valves increase the process safety of the entire system, helping to cut costs associated with breakdown and maintenance. The solenoid valves can be used in all kinds of applications and meet the highest safety standards (up to SIL3, explosion protection). This is backed by TÜV certificates up to SIL3 in accordance with IEC 61508.

Sturdy for use in harsh environments

The surface of the valve housing is treated with hard Ematal.

This treatment involves converting the aluminum surface into a very hard aluminum oxide layer with titanium oxide intercalations.

This makes the valves extremely resistant to wear and abrasion and gives them first-class sliding qualities. This provides optimum protection against atmospheric and chemical influences.